What's New in MAGMAhpdc?

What's New in MAGMAhpdc?

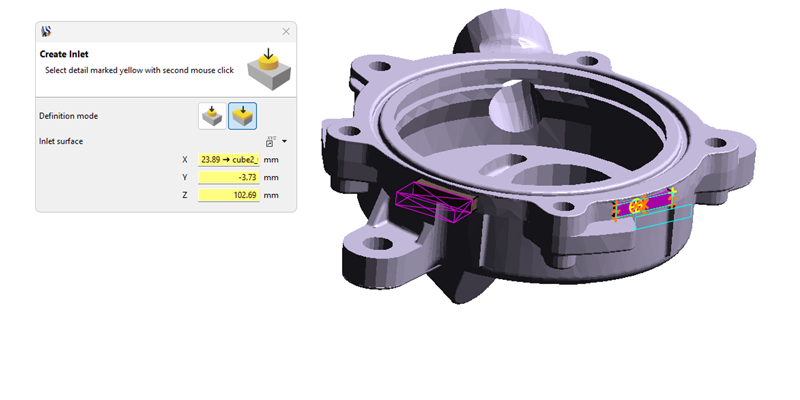

MAGMAhpdc offers new functionalities for component design that make it possible to work even in the early planning phase without having to specify the casting system or the machine. With the "Virtual Gate" function, die casters can position multiple inlets on the casting and directly reference the gating system to them. This allows a quick and efficient initial assessment of the die filling process without having to define a complete casting system or specific shot parameters.

In addition, it is possible to flexibly adjust casting conditions to the project status, for example, with regard to pouring times, pouring rates or pressure curves during the shot. These functionalities facilitate the early evaluation of the die filling process and support targeted component design.

Highlights:

- Early component design: Works without explicitly defining the casting system or machine.

- Virtual gate: Enables a fast and efficient evaluation of the die filling process by simply defining gates directly on the casting.

- Reduced model: use of a reduced model for a quick and precise initial assessment

- Flexible casting conditions: adjustment of pouring times, pouring rates and pressure curves depending on the project status

- Targeted component design: support through simple evaluation of the die filling process in the early planning phase

Latest Publication

MAGMASOFT® 6.1 – Advancing Low Pressure Die Casting and Sustainability

With extensive revisions and new functionalities, MAGMASOFT® enhances the simulation of low pressure die casting processes, and expands the capabilities for die casters and users of MAGMA CC and MAGMA C+M. For the first time, MAGMASOFT® includes a dedicated process module for rheocasting and thixomolding. In addition, a new ECONOMICS perspective enables users to quantitatively assess costs and CO₂.

System Requirements

MAGMASOFT® is available for all suitable current operating systems such as Linux and Windows. MAGMASOFT® can be used on dual or multi-processor computers or massively parallel on cluster computers.