Steel Continuous Casting Excellence With MAGMA CC

Committed to casting excellence, MAGMA CC delivers robust solutions for steel continuous casting, emphasizing the design of process conditions to optimize product quality. This comprehensive solution offers a streamlined process, covering flow and solidification evaluation, stress, and crack assessment. It forms an integrated process chain for casting and forming.

MAGMA CC Capabilities in Steel Continuous Casting:

- Comprehensive prediction of all process steps in continuous casting.

- Offering a virtual test environment for productivity optimization.

- Enabling quick decision-making and time savings for all parties involved.

- Proactive quality management by understanding process fluctuations.

- Enhancing communication and cooperation within organizations and with customers.

Process Design and Optimization Features:

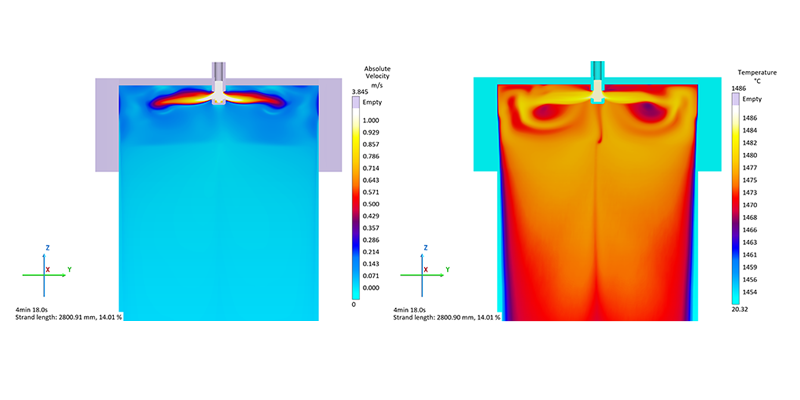

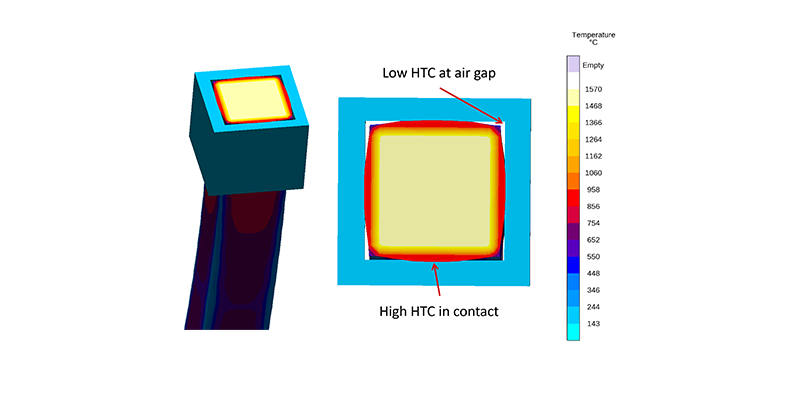

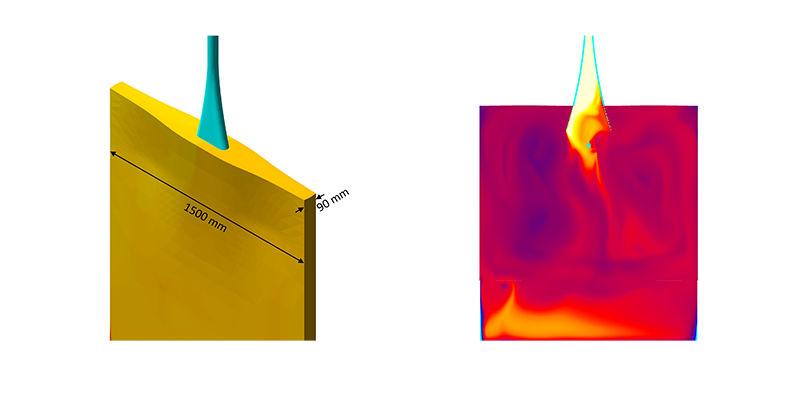

- Representation of the entire and integrated continuous casting process, assessing thermal, flow, and stress-related factors

- Segregation and prediction of solidification structure

- Prediction of inclusions and optimization of cleanliness throughout the process in the tundish and in the mold

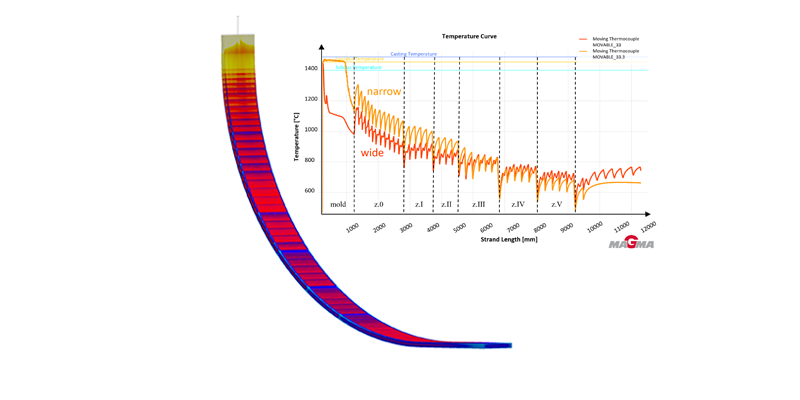

- Calculation of the solidification front to avoid quality defects

- Fully integrated electromagnetic stirring (EMS) module for assessing flow conditions and the impact on heat and mass transfer, and shell thickness growth

- Accurate prediction of the metallurgical length

- Evaluation of optimal process parameters and robust process conditions

Publication in Area of Continuous Casting

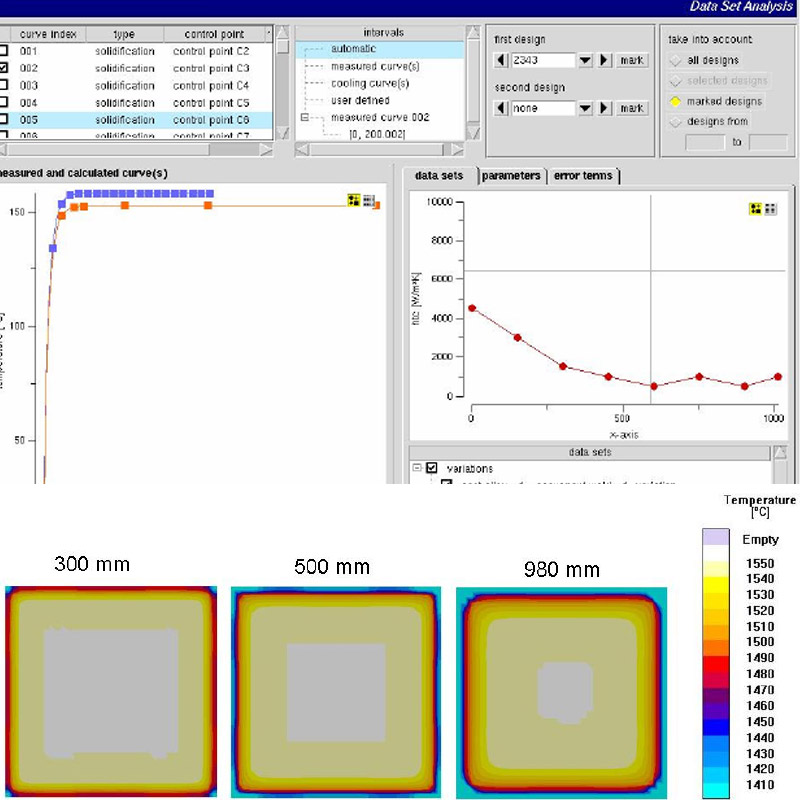

Autonomous Mathematical Optimization of Continuous Casting Processes

Editors:

Wilfried Schäfer, Götz Hartmann, Erik Hepp, MAGMA GmbH, Aachen, Germany

Dieter G. Senk, Sonja Stratemeier, IEHK RWTH Aachen University, Germany

The publication introduces a numerical simulation based optimization strategy, following rigorous thermodynamic and thermo mechanical models as well as a strictly methodic approach.